JIT

Just in Time (JIT) is an inventory management method that is designed to cut costs and increase efficiency by receiving goods when they are needed in-store.

JIT stands for just-in-time, and it helps reduce inventory holding costs and time and increase the turnover of the store. With the help of just-in-time techniques, you did not need to store large amounts of merchandise inventory or materials, you just needed or could store much smaller rotating stock.

JIT is a workflow technique aimed at reducing flow times within the supply chain, as well as response times from suppliers, stores, and customers.

When you order such items, then the main intention of this stock is to be used immediately upon arrival and will spend as little time in your storage area. This method is best used for stores that have shorter demands.

It is often used by the food industry, technology manufacturers, and book publishers. These industries need to make items quickly to keep up with trends and avoid excess products when that trend and demand fall.

Konigle's Shopify Dead Stock Prevention Tool helps you to automatically prevent dead stock prevention on Shopify stores.

Benefits of JIT

If you sell your product in a retail or an online store then need to know the benefit of JIT for your e-commerce business.

Manufacturing: Just-in-time manufacturing benefits include reducing inventory and labor costs, increasing the production of goods, and improving product quality.

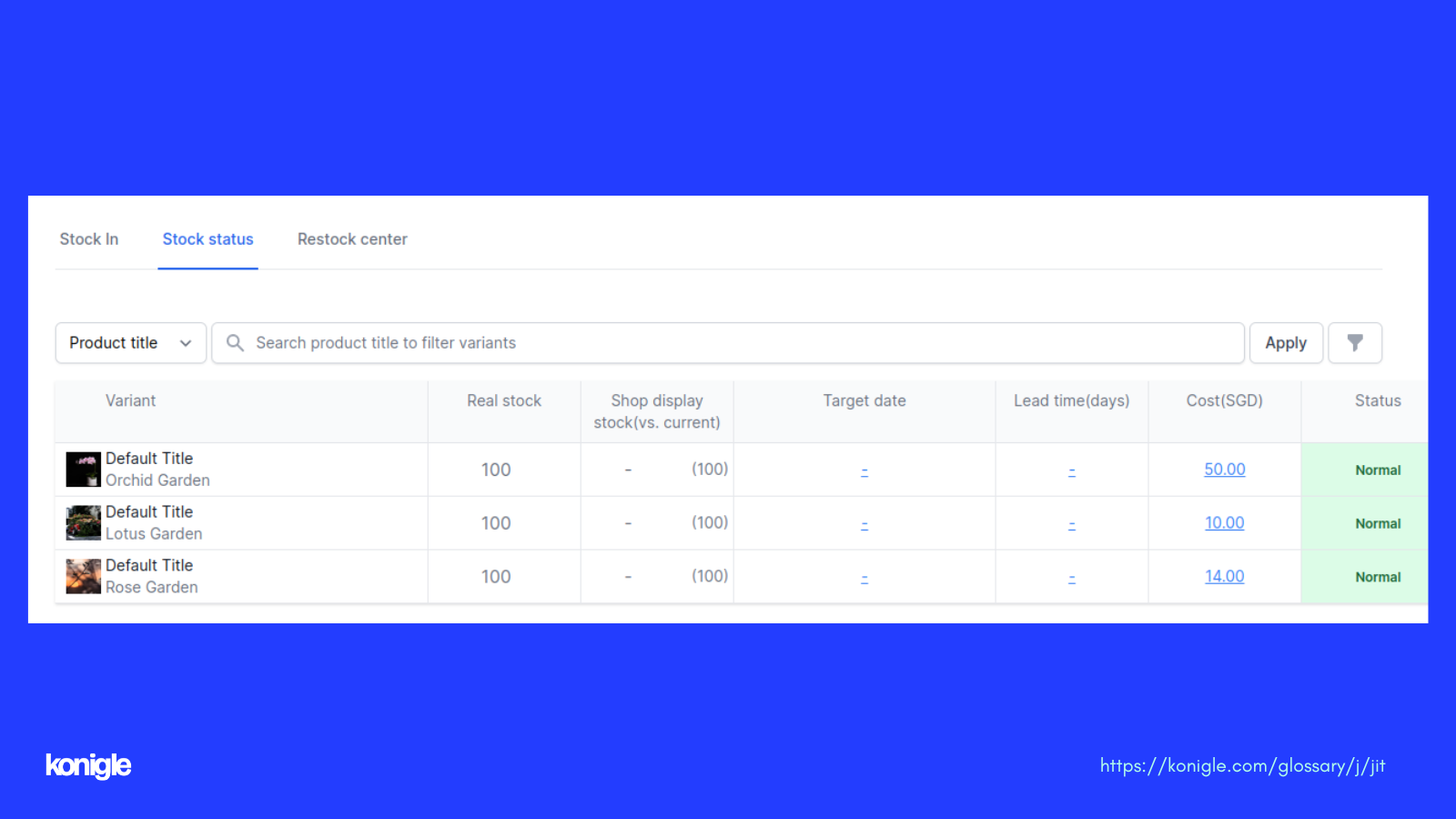

Konigle's smart inventory management for Shopify stores helps you to manage inventory, save time, and increase profits.

Supply: For suppliers, JIT reduces the space that they needed to operate and reduces WIP (work in process).

Store: It helps in the reduction of throughput time, also reduces standard hours, and increases the number of shipments for your e-commerce website.

How does just-in-time work?

The process of just in time is very simple:

- Customer place an order on your eCommerce store.

- After receiving the order, the store owner or manufacturer orders the material or product.

- After the supplier receives the order, deliver the required material to the store owner.

- After receiving a product or material from the supplier, Assemble the product.

- Then fulfilled the order of the customer

- Customer received the final product

Here is a video that explains how Konigle's inventory management tool works.

What is an example of a JIT?

As you know, JIT is a production strategy that's all about producing goods or delivering services just in time to meet customer demand.

One great example of a JIT system is the Toyota Production System, which completely transformed the automotive industry by adopting a lean manufacturing approach. This amazing system focuses on manufacturing vehicles based on real customer orders, ensuring maximum efficiency and customer satisfaction.

By implementing just-in-time manufacturing techniques in inventory management, companies can effectively reduce the need for excessive inventory. This not only improves efficiency and reduces costs but also enhances customer satisfaction.

Different Types of Just-In-Time Manufacturing

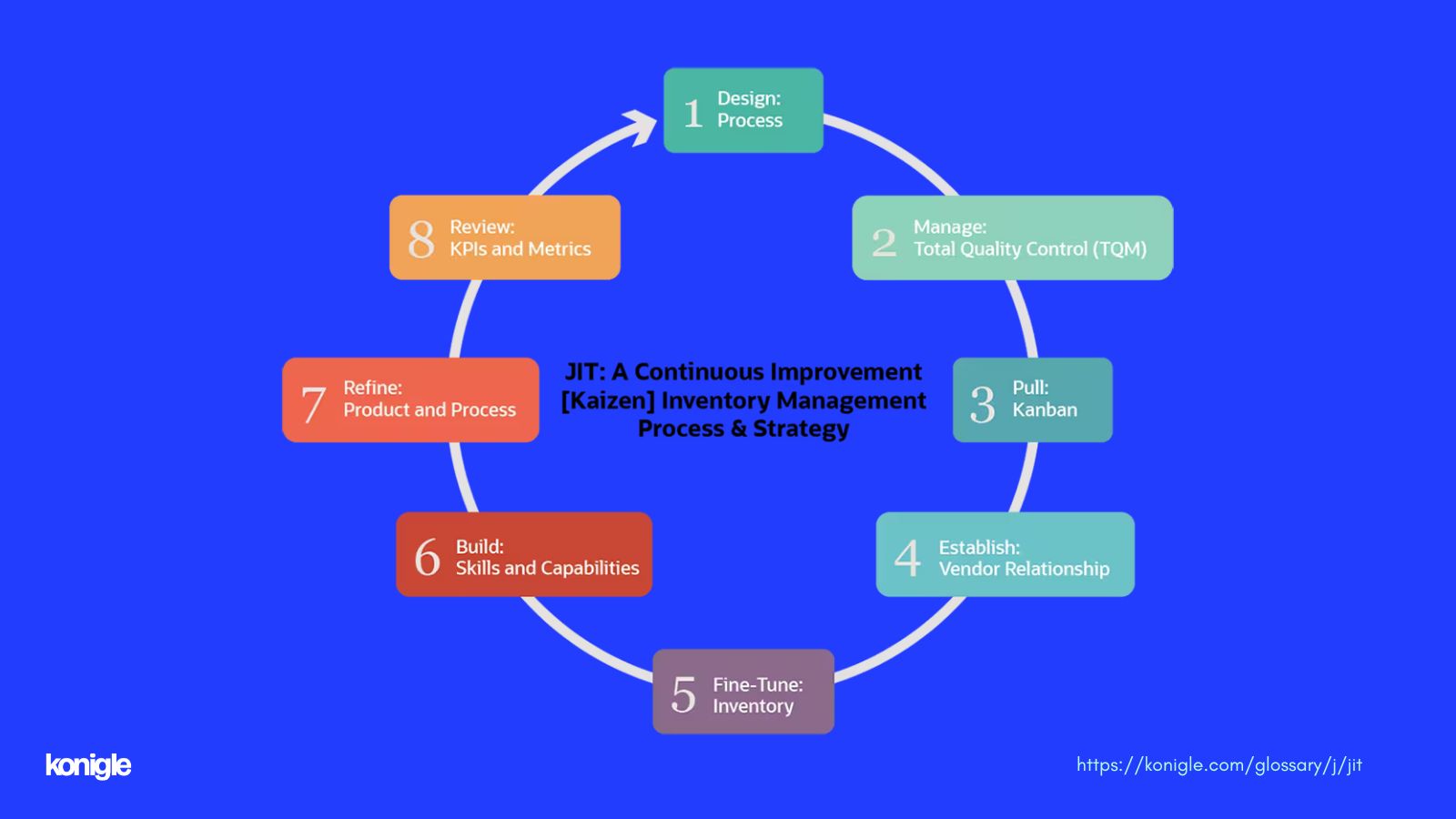

The core concepts of JIT manufacturing remain consistent across different industries. However, there are various types or approaches that can be selected depending on specific needs and requirements. Let's dive into some of the different types of just-in-time manufacturing:

1. Lean Manufacturing

Lean manufacturing is a widely embraced approach to JIT that puts a strong emphasis on eliminating waste and maximizing value. It involves streamlining processes, reducing inventory levels, and continuously striving to improve efficiency.

2. Kanban System

The Kanban system is an awesome visual scheduling system that helps you manage inventory levels and production flow. It uses cards or signals to indicate when more items need to be produced and when they need to be replenished.

3. Just-In-Sequence (JIS)

Just-In-Sequence is a JIT approach that is often used in automotive manufacturing. It is a process where parts or components are delivered to the assembly line in the exact sequence that they are needed, ensuring smooth operations and efficient production.

4. Continuous Flow Manufacturing

Continuous flow manufacturing is all about creating a smooth and uninterrupted production process. It's all about making things more efficient by reducing the size of batches, cutting down on setup times, and ensuring a constant flow of materials and information.

5. Demand-Driven Manufacturing

Demand-driven manufacturing is an alternative approach to JIT that puts a strong focus on creating goods based on the actual needs of customers. It involves carefully keeping track of market demand and making necessary adjustments in production accordingly.

These examples showcase the various types of just-in-time manufacturing. Each approach has its own set of advantages and factors to consider, allowing companies to select the one that aligns with their unique circumstances and objectives.

Advantages of JIT

- Reduce defective product loss

- Increase Inventory Turnover

- Minimize raw materials for storage

- Faster product turnaround

- Smoother production flow

- Shorter production runs

- Lower holding costs

- Reduce labor costs

- Reduce Work-in-Progress (WIP)

Disadvantages of JIT

- Supply chain disturbance

- Missed unexpected orders

- If Costs rise of the parts, profit margins drop

- Stock-outs disturb orders

- Time Pressure to complete order